I've noodled on designing an all-in-one computer/CNC machine for years. Something that would combine the software needed to design things with the hardware needed to fab them into a portable, well-integrated machine. I want this for myself so I have an easy way to take the tools I enjoy in the lab with me for demos, teaching or just for fun (imagine sitting under a tree in the woods hacking on a new gadget!). Perhaps more importantly I've wanted to design & build this for others who have ideas to realize through such a machine but not the time, space or other resources to own or access the various components of such a machine and work through the difficulties of getting all the parts (hardware and software) to work correctly.

In short, I want to make a personal factory that "just works"...

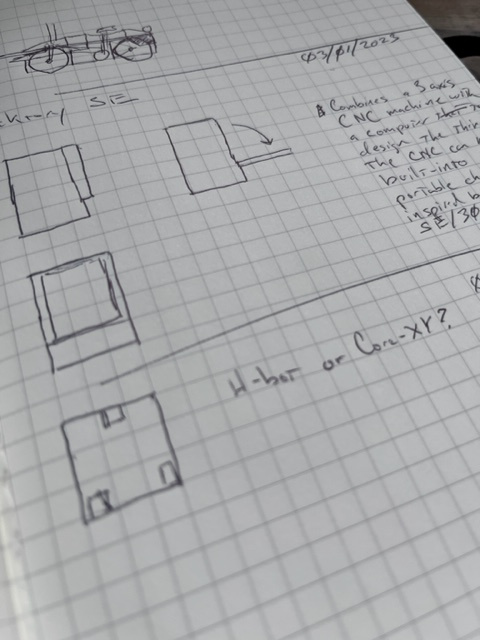

This went through several iterations over the years, but when I saw an old Macintosh SE sitting next to my (unfinished) Tantillus 3D printer, the perfect design came to me.

Of course during the pandemic I had less use for anything portable, but recently the idea of having such a machine has become interesting again. Perhaps even more important I came-up with a name (names being the hard part) and so now I could finally save the file and get on with it.

The SE/3D won't be the 3D printer I've built, but it will be the first I've designed myself. It also won't be the first computer I've built, but it will be the most challenging to design from a mechanical engineering perspective. I have a fairly ambitious list of design requirements, so if I'm going to achieve them I have my work cut out for me.

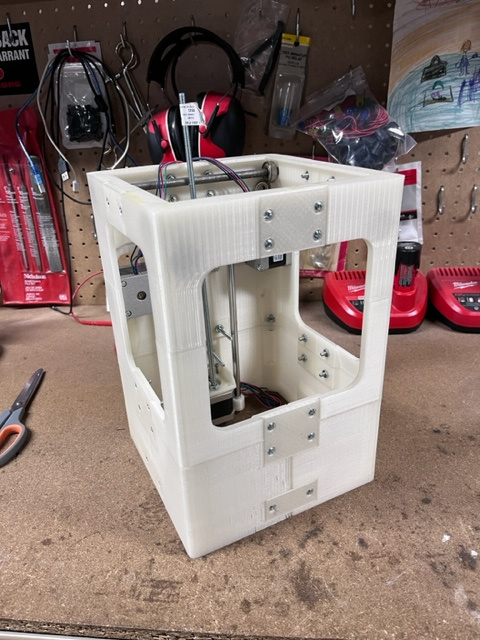

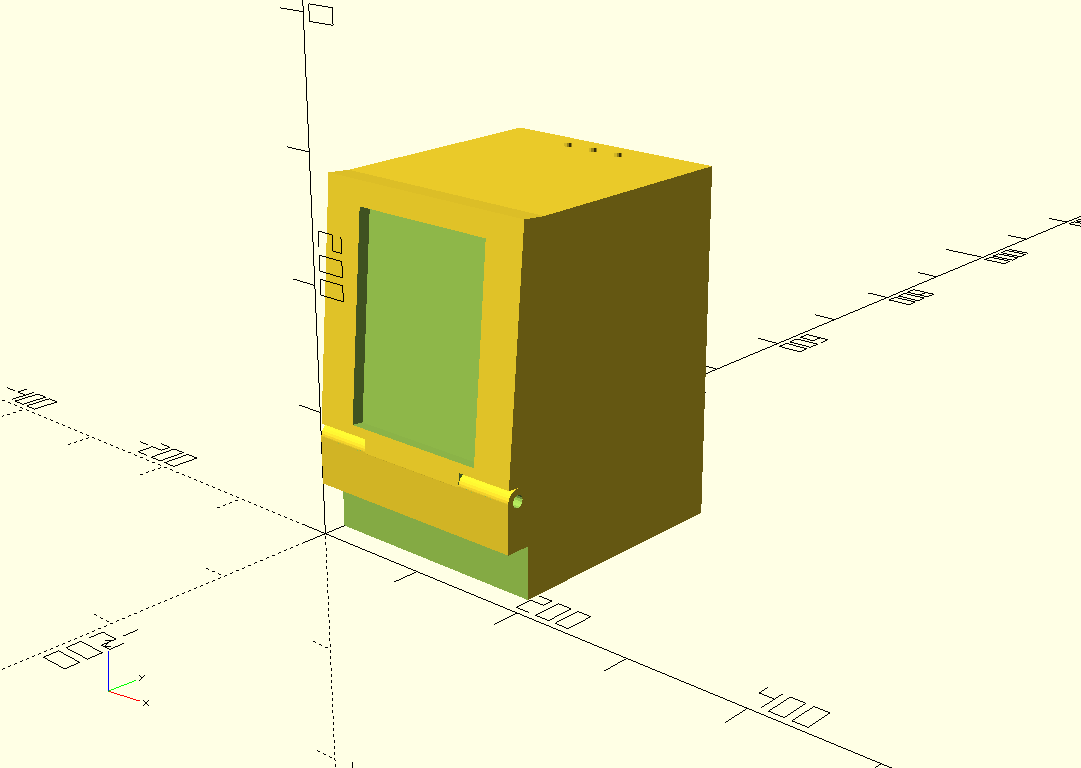

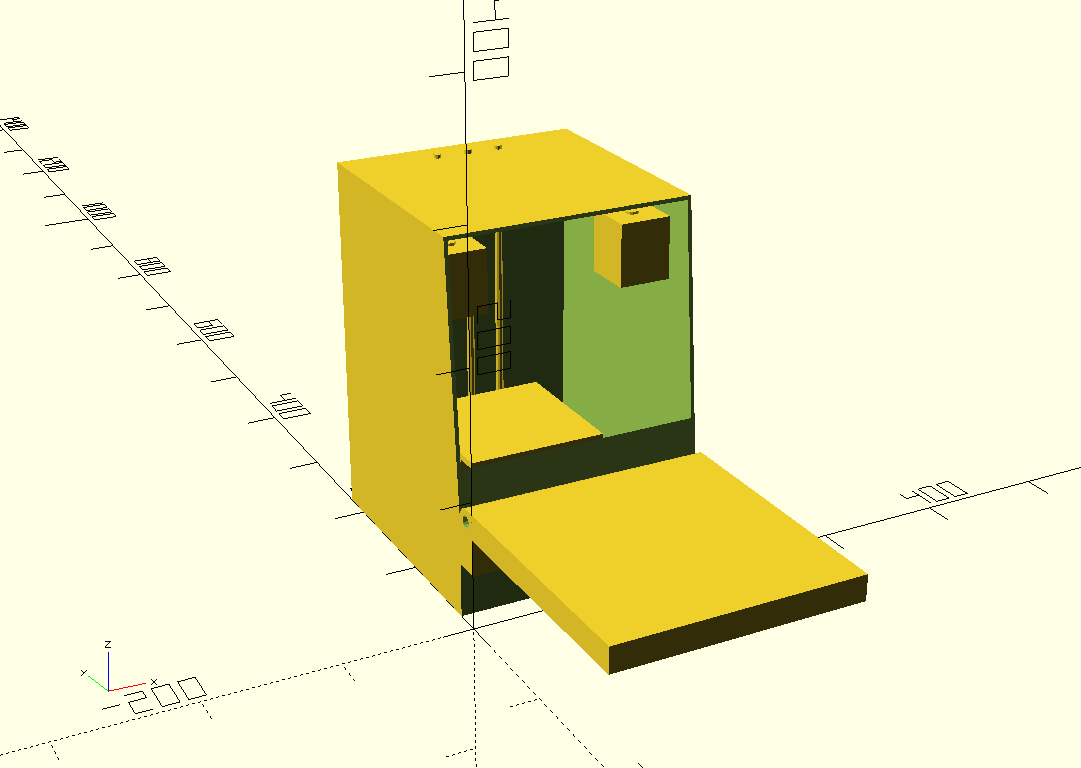

Externally SE/3D bears a strong resemblance to the classic all-in-one Macintosh from which its name derives. Internally it's quite a different story.

In place of the bulky CRT display tube and computing hardware is a 3-axis CNC robot. As the name implies this CNC's primary design is aimed at 3D printing, however I'm planning to take it further than that if possible. Minimally a solid-state laser will provide cutting/engraving capability and ideally I want to include some amount of milling ability as well (enough to create circuit boards). With these three abilities, SE/3D becomes a stand-alone electronics factory.

The front panel of SE/3D folds down to reveal the internal CNC robot as well as providing a work surface for soldering, assembly and testing.

In addition to CNC capabilities, SE/3D will include storage, power and I/O connections for soldering and assembling the hardware that it produces. Additionally, electronics testing (VOM and oscilloscope software) and of course firmware development and debugging will complete the package.

As always the design will be completely open and I will be selecting "minerals" that are as free and open as I can find. Design files are hosted in my general-purpose model repository for now, but will probably migrate to a dedicated repository once I finalize the design.

I would love to make it a true Reprap with the ability to reproduce, but given the portability constraints that may not be possible (if not I have ideas for making it possible via an "intermediate" form... more on that later).

If you'd like to follow along, I'll be posting major updates here but more frequent updates on this project to the fediverse under the #se3d hashtag.